Fundamentals of Electrostatic Discharge

Part One — An Introduction to ESD

History & Background

To many people, static electricity is little more than the shock experienced when touching a metal doorknob after walking across a carpeted room or sliding across a car seat. However, static electricity has been a serious industrial problem for centuries. As early as the 1400’s, European and Caribbean forts were using static control procedures and devices to prevent electrostatic discharge ignition of black powder stores. By the 1860’s, paper mills throughout the U.S. employed basic grounding, flame ionization techniques, and steam drums to dissipate static electricity from the paper web as it traveled through the drying process. The age of electronics brought with it new problems associated with static electricity and electrostatic discharge. And, as electronic devices became faster and smaller, their sensitivity to ESD increased. Today, ESD impacts productivity and product reliability in virtually every aspect of today’s electronics environment. Many aspects of electrostatic control in the electronics industry also apply in other industries such as clean room applications and graphic arts.

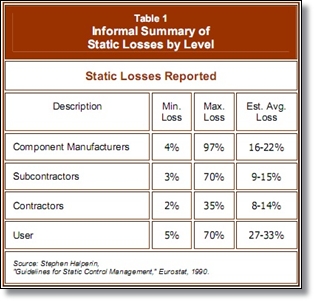

Despite a great deal of effort during the past decade, ESD still affects production yields, manufacturing costs, product quality, product reliability, and profitability. Industry experts have estimated average product losses due to static to range from 8-33% (Table 1). Others estimate the actual cost of ESD damage to the electronics industry as running into the billions of dollars annually. The cost of damaged devices themselves ranges from only a few cents for a simple diode to several hundred dollars for complex hybrids. When associated costs of repair and rework, shipping, labor, and overhead are included, clearly the opportunities exist for significant improvements

Static Electricity: Creating Charge

Static electricity is defined as an electrical charge caused by an imbalance of electrons on the surface of a material. This imbalance of electrons produces an electric field that can be measured and that can influence other objects at a distance. Electrostatic discharge is defined as the transfer of charge between bodies at different electrical potentials.

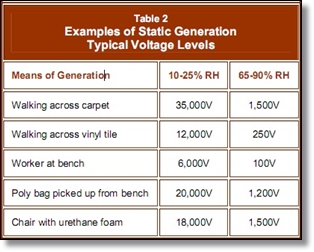

Controlling electrostatic discharge begins with understanding how electrostatic charge occurs in the first place. Electrostatic charge is most commonly created by the contact and separation of two materials. For example, a person walking across the floor generates static electricity as shoe soles contact and then separate from the floor surface. An electronic device sliding into or out of a bag, magazine or tube generates an electrostatic charge as the device’s housing and metal leads make multiple contacts and separations with the surface of the container. While the magnitude of electrostatic charge may be different in these examples, static electricity is indeed generated.

|  |

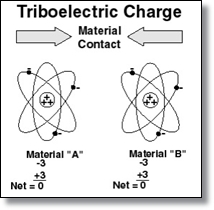

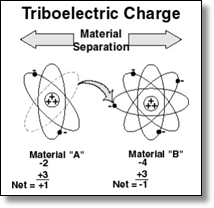

| Figure 1 The Triboelectric Charge. | Figure 2 The Triboelectric Charge – Separation |

Creating electrostatic charge by contact and separation of materials is known as “triboelectric charging.” It involves the transfer of electrons between materials. The atoms of a material with no static charge have an equal number of positive (+) protons in their nucleus , negative (-) electrons orbiting the nucleus. In Figure 1, Material “A” consists of atoms with equal numbers of protons and electrons. Material B also consists of atoms with equal (though perhaps different) numbers of protons and electrons. Both materials are electrically neutral. When the two materials are placed in contact and then separated, negatively charged electrons are transferred from the surface of one material to the surface of the other material. Which material loses electrons and which gains electrons will depend on the nature of the two materials. The material that loses electrons becomes positively charged, while the material that gains electrons is negatively charged. This is shown in Figure 2.Static electricity is measured in coulombs. The charge “q” on an object is determined by the product of the capacitance of the object “C” and the voltage potential on the object (V): q=CV Commonly, however, we speak of the electrostatic potential on an object, which is expressed as voltage. This process of material contact, electron transfer and separation is really a more complex mechanism than described here. The amount of charge created by triboelectric generation is affected by the area of contact, the speed of separation, relative humidity, and other factors. Once the charge is created on a material, it becomes an “electrostatic” charge (if it remains on the material). This charge may be transferred from the material, creating an electrostatic discharge, or ESD, event. Additional factors such as the resistance of the actual discharge circuit and the contact resistance at the interface between contacting surfaces also affect the actual charge that can cause damage.

An electrostatic charge also may be created on a material in other ways such as by induction, ion

bombardment, or contact with another charged object. However, triboelectric charging is the most common.

How Material Characteristics Affect Static Charge

Triboelectric Series

When two materials contact and separate, the polarity and magnitude of the charge are indicated by the materials’ positions in the triboelectric series. The triboelectric series tables show how charges are generated on various materials. When two materials contact and separate, the one nearer the top of the series takes on a positive charge, the other a negative charge. Materials further apart on the table typically generate a higher charge than ones closer together. These tables, however, should only be used as a general guide because there are many variables involved that cannot be controlled well enough to ensure repeatability. A typical triboelectric series is shown in Table 3.

| Virtually all materials, including water and dirt particles in the air,can be triboelectrically charged. How much charge is gen, where that charge goes, and how quickly, are functions of the materials’ electrical characteristics. Insulative Materials A material that prevents or limits the flow of electrons across its surface or through its volume is called an insulator. Insulators have an extremely high electrical resistance, generally greater than 1 x 10E12 ohms/sq (surface resistivity) and 1 x 10E11 ohm-cm (volume resistivity). A considerable amount of charge can be generated on the surface of an insulator. Because an insulative material does not readily allow the flow of electrons, both positive and negative charges can reside on insulative surface at the same time, although at different locations. The excess electrons at the negatively charged spot might be sufficient to satisfy the absence of electrons at the positively charged spot. Conductive Materials A conductive material, because it has low electrical resistance, allows electrons to flow easily across its surface or through its volume. Conductive materials have low electrical resistance, generally less than 1 x 10E5 ohms/sq (surface resistivity) and 1 x 10E4 ohm-cm (volume resistivity). When a conductive material becomes charged, the charge (i.e., the deficiency or excess of electrons) will be uniformly distributed across the surface of the material. If the second conductor is attached to an earth grounding point, the electrons will flow to ground and the excess charge on the conductor will be “neutralized.” |

Static Dissipative Materials

Static dissipative materials have an electrical resistance between insulative and conductive materials (1 x 10E5 – 1 x 10E12 ohms/sq (surface resistivity) and 1 x 10E4 – 1 x 10E11 ohm- cm (volume resistivity). There can be electron flow across or through the dissipative material, but it is controlled by the surface resistance or volume resistance of the material. As with the other two types of materials, charge can be generated triboelectrically on a static dissipative material. However, like the conductive material, the static dissipative material will allow the transfer of charge to ground or other conductive objects. The transfer of charge from a static dissipative material will generally take longer than from a conductive material of equivalent size. Charge transfers from static dissipative materials are significantly faster than from insulators, and slower than from conductors.

Electrostatic Fields

Charged materials also have an electrostatic field and lines of force associated with them. Conductive objects brought into the vicinity of this electric field will be polarized by a process known as induction. A negative electric field will repel electrons on the surface of the conducting item that is exposed tothe field. A positive electric field will attract electrons to near the surface thus leaving other areas positively charged. No change in the actual charge on the item will occur in polarization. If, however, the item is conductive or dissipative and is touched to ground while polarized, charge will flow from or to ground to compensate for the charge imbalance. If the electrostatic field is removed and the ground contact disconnected, the charge will be trapped on the item. If a nonconductive object is brought into the electric field, the electrical dipoles will tend to align with the field creating apparent surface charges. A nonconductor cannot be charged by induction.

ESD Damage-How Devices Fail

Electrostatic damage to electronic devices can occur at any point from manufacture to field service. Damage results from handling the devices in uncontrolled surroundings or when poor ESD control practices are used. Generally damage is classified as either a catastrophic failure or a latent defect.

Catastrophic Failure

When an electronic device is exposed to an ESD event, it may no longer function. The ESD event may have caused a metal melt, junction breakdown, or oxide failure. The device’s circuitry is permanently damaged causing the device fail. Such failures usually can be detected when the device is tested before shipment. If the ESD event occurs after test, the damage will go undetected until the device fails in operation.

Latent Defect

A latent defect, on the other hand, is more difficult to identify. A device that is exposed to an ESD event may be partially degraded, yet continue to perform its intended function. However, the operating life of the device may be reduced dramatically. A product or system incorporating devices with latent defects may experience premature failure after the user places them in service. Such failures are usually costly to repair and in some applications may create personnel hazards.

Basic ESD Events–What Causes Electronic Devices to Fail?

ESD damage is usually caused by one of three events: direct electrostatic discharge to the device, electrostatic discharge from the device or field-induced discharges. Damage to an ESDS device by the ESD event is determined by the device’s ability to dissipate the energy of the discharge or withstand the voltage levels involved. This is known as the device’s “ESD sensitivity.

Discharge to the Device

An ESD event can occur when any charged conductor (including the human body) discharges

to an ESDS (electrostatic discharge sensitive) device. The most common cause of electrostatic damage is the direct transfer of electrostatic charge from the human body or a charged material to the electrostatic discharge sensitive (ESDS) device. When one walks across a floor, an electrostatic charge accumulates on the body. Simple contact of a finger to the leads of an ESDS device or assembly allows the body to discharge, possibly causing device damage. The model used to simulate this event is the Human Body Model (HBM). A similar discharge can occur from a charged conductive object, such as a metallic tool or fixture. The model used to characterize this event is known as the Machine Model.

Summary

In this introductory article on electrostatic discharge, we have discussed the basics of electrostatic charge and discharge, types of failures, ESD events, and device sensitivity. We can summarize this discussion as follows:

- Virtually all materials, even conductors, can be triboelectrically charged.

- The level of charge is affected by material type, speed of contact and separation, humidity, and several other factors.

- Electrostatic fields are associated with charged objects.

- Electrostatic discharge can damage devices so they fail immediately, or ESD may result in latent damage that may escape immediate attention, but cause the device to fail prematurely once in service.

- Electrostatic discharge can occur throughout the manufacturing, test, shipping, handling, or operational processes.

- Component damage can occur as the result of a discharge to the device, from the device, or from charge transfers resulting from electrostatic fields. Devices vary significantly in their sensitivity to ESD. Protecting your products from the effects of static damage begins by understanding these key concepts of ESD. Armed with this information, you can then begin to develop an effective ESD control program.

Comments are closed